Article Development

Ceramic tableware is a synthesis of individual design and a fascinating natural material—a symbol of culture and style, at once convenient and sustainable.

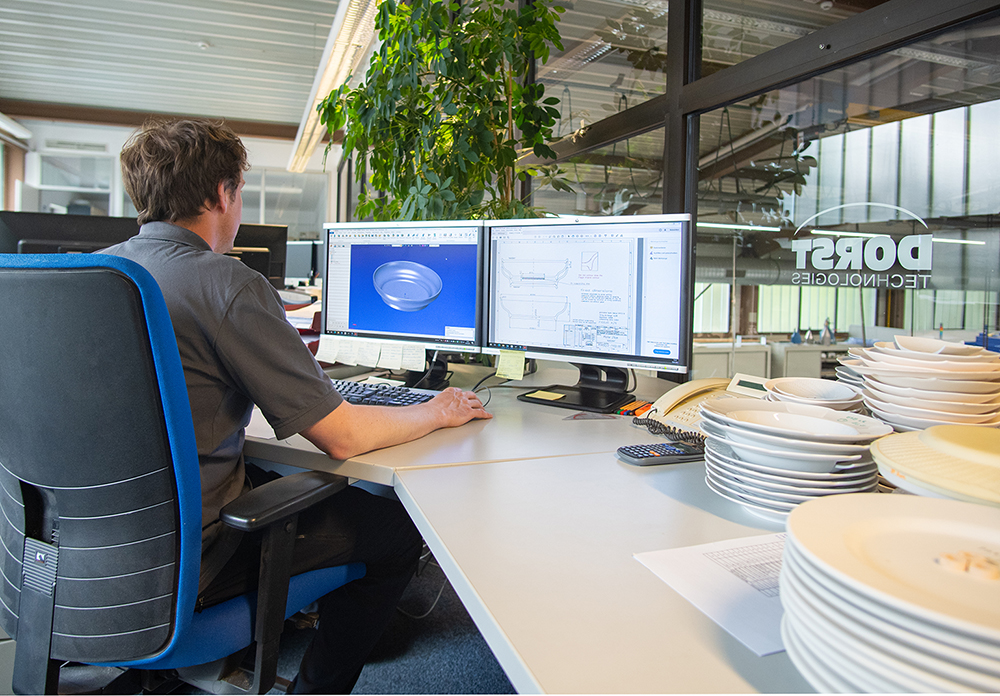

DORST TECHNOLOGIES' isostatic tool-making shop has always known how to turn customer-specific design ideas into pressing tools suitable for industrial production and how to raise them to a stable production stage. In case of a change in procedure, it is easily possible to transfer the articles manufactured so far by means of plastic shaping to more economic isostatic dry pressing.

Irrespective of whether you present us with a manually molded sample, a scanned point cloud or an article designed in 3D CAD, we always have the right resources and the ceramic know-how to turn it into a customer-specific isostatic pressing tool.

Unique flexibility, adjustability and economic efficiency are the prominent features of our DORST tool system when being combined with our isostatic tableware presses. The tools are designed in such a way that the inevitable flash will be as small as possible, thus reducing the consumption of valuable raw materials.

For the sampling of tools, we offer our customers the entire process chain starting with the production of granules by means of spray drying, continuing with the forming of articles on original production presses and completing the process with biscuit firing of pressed tableware articles.

Our tool designers, process engineers and materials specialists are ready to assist you at all stages of the tool development process:

- Conditioning and optimization of granules capable of being pressed

- Designing of tableware articles

- Realization of existing designs, bearing in mind pressing-related aspects of tool construction

- Designs for DORST tool systems as well as third-party systems

- Manufacturing of tools, elastic membranes and coatings

- Commissioning of the tools on in-house standard presses

- Sampling of the tools with customer material

- Biscuit firing and comparison with the furnace curves at the customer's site

- On-site service and consulting

Benefit from our broad expert knowledge when realizing your tableware article projects and receive everything from one single source, thus reducing your time to market.