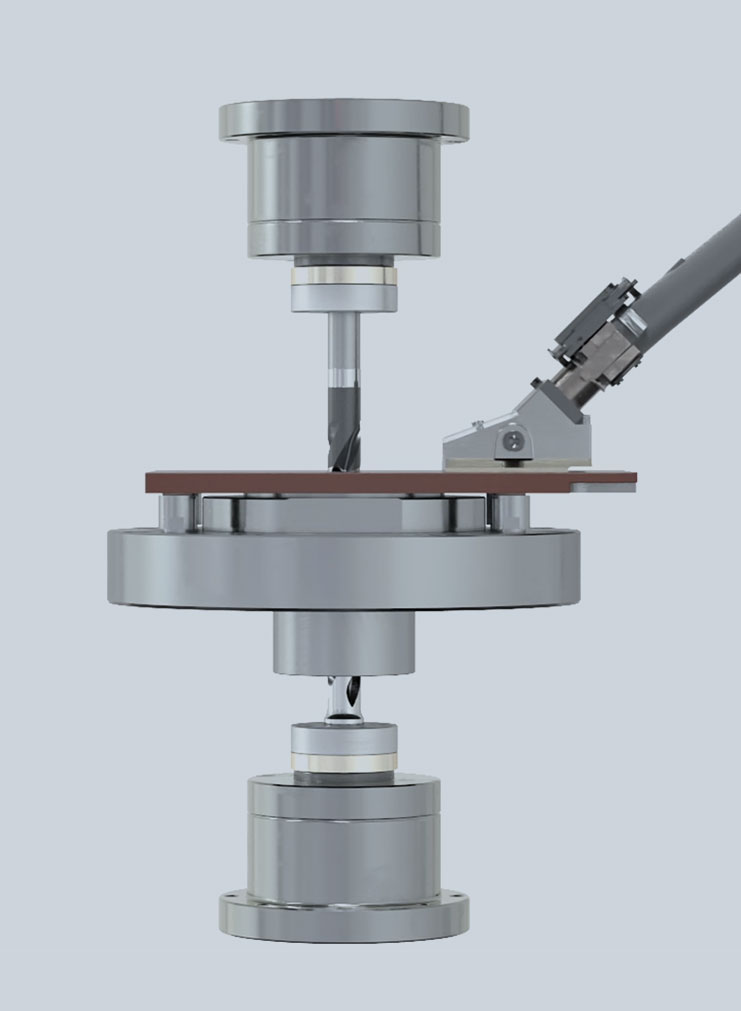

Axial Powder Presses

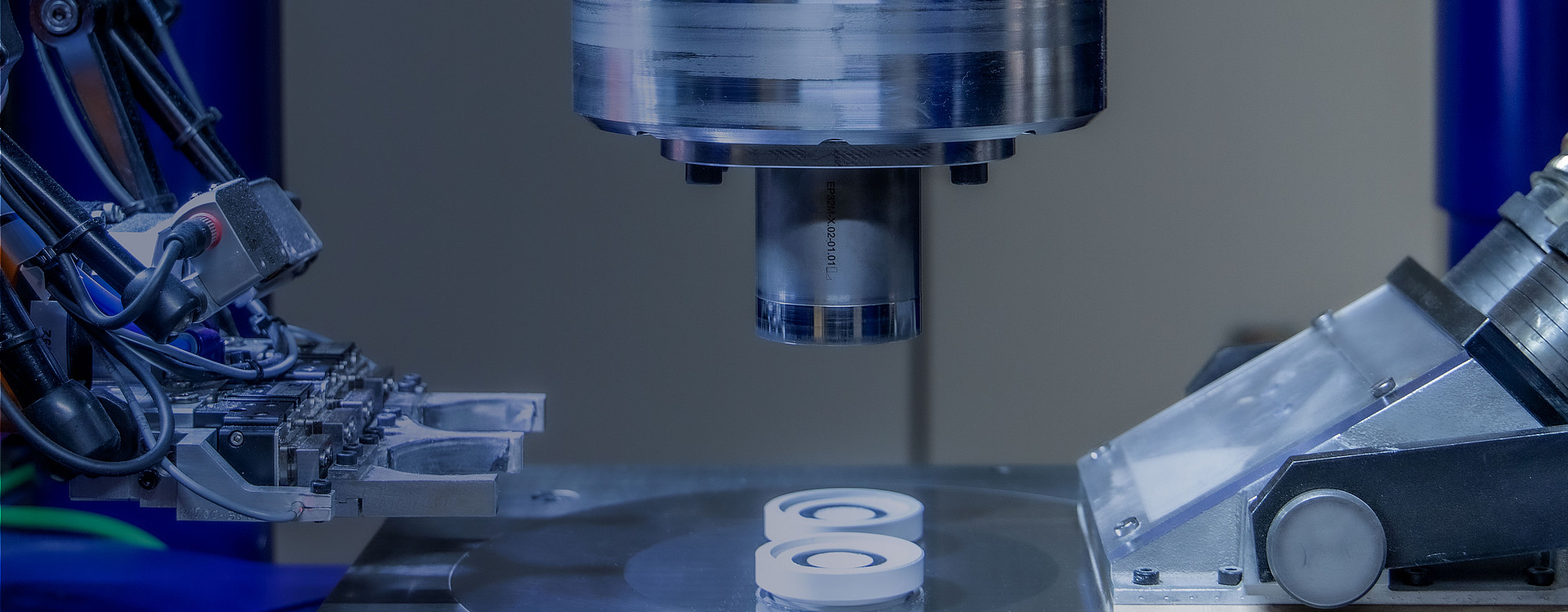

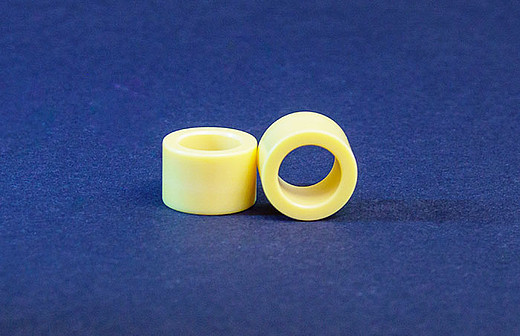

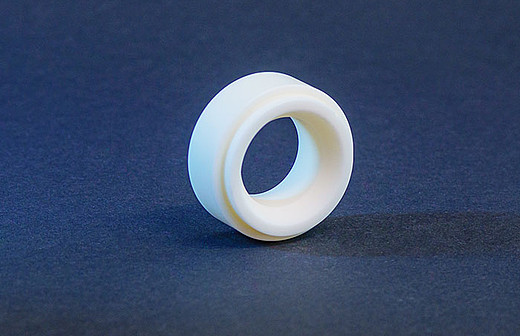

DORST TECHNOLOGIES has always been a pioneer and technological leader when it came to the development of axial powder presses for metal powders, technical ceramic materials, hard metals and other powder materials.

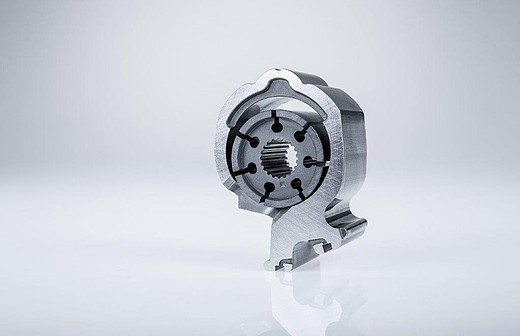

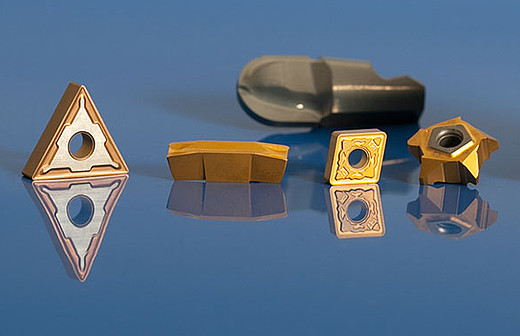

Products at a glance