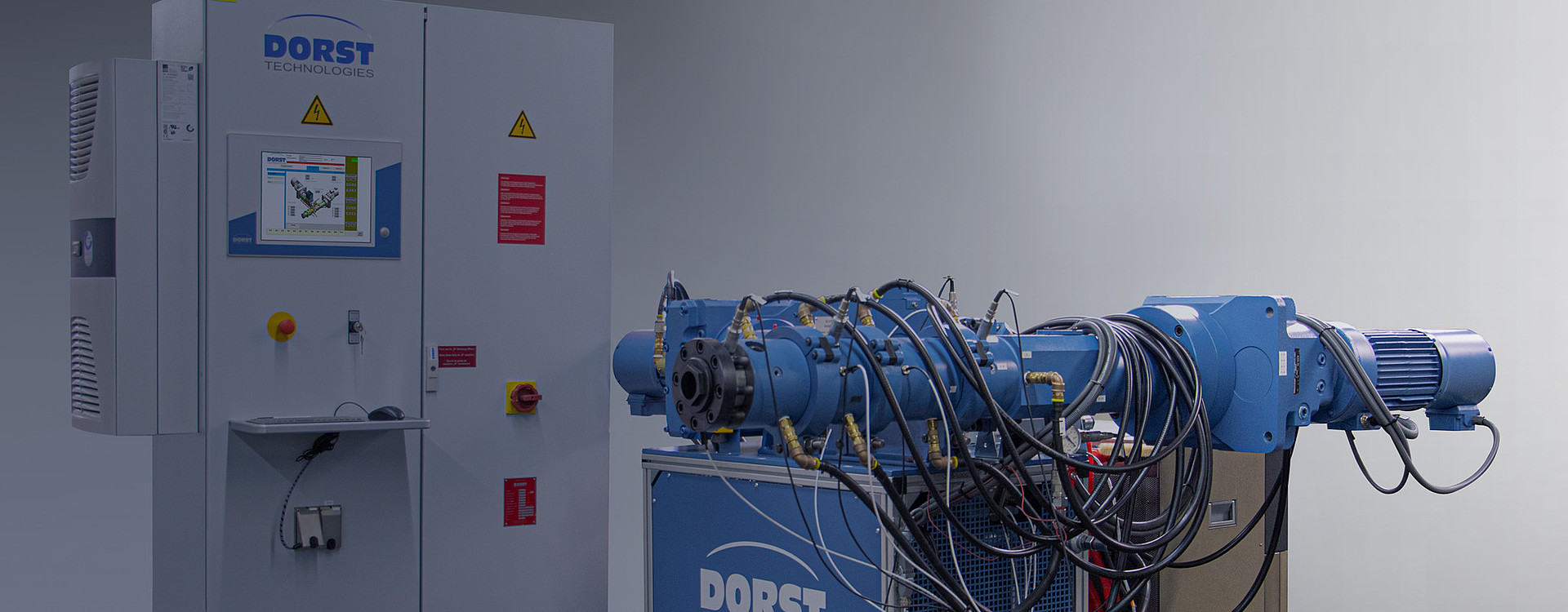

Vacuum Extrusion Presses

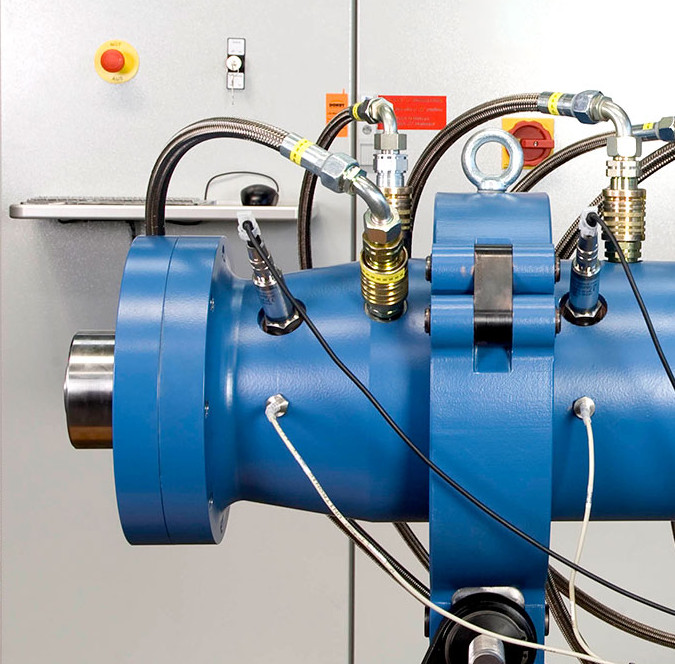

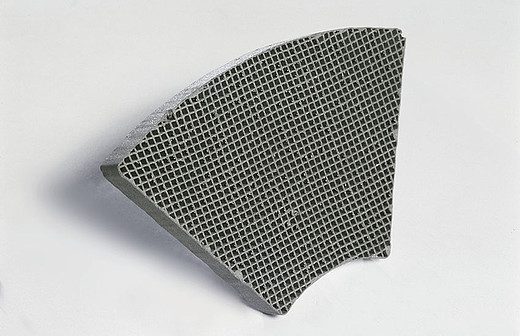

DORST TECHNOLOGIES' vacuum extrusion presses are a reliable industry solution with decades of proven performance used for the continuous extrusion of profiles made of technical ceramics, hard metals or other plastified materials difficult to extrude.

Products at a glance