Mobile Hydraulic Check

Leakages and failures in the hydraulic system of your press pose a threat to its operational readiness and production reliability. The diagnostics of defective hydraulic components such as valves are very costly and time-consuming, however, preventive replacement seldom proves to be economical.

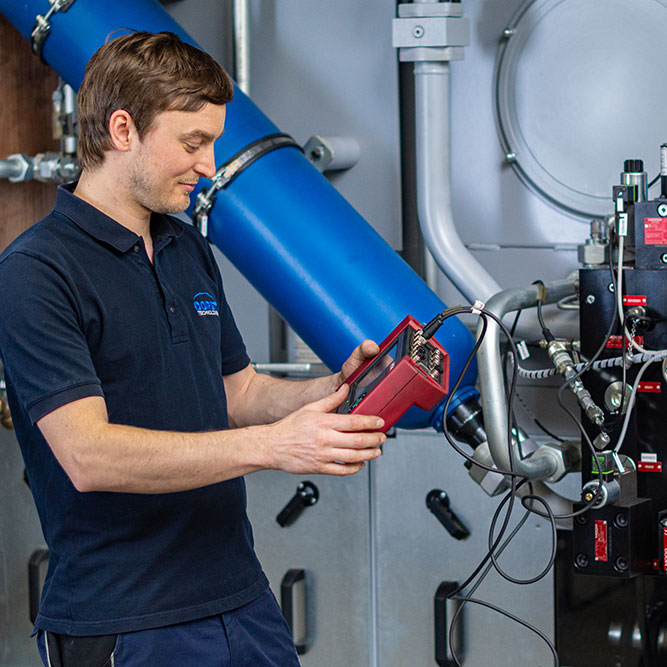

Our mobile hydraulic test bench enables us to provide you with dependable information as to the wear condition of the components of your hydraulic system, allowing us to localize and eliminate internal leakages and problems in the hydraulic system of your plant swiftly and reliably. By determining and monitoring the development of the wear condition of installed components, we are able to offer you condition-based, cost-effective predictive maintenance.

By adjusting and optimizing specific parameters such as pump characteristic curve or valve switching times, our service engineers will restore the operational performance of your hydraulic system and even enhance it in many cases. This will have a direct impact on the stroke rate and thus the economic efficiency of your machine and, as a result, on its output.

- Detailed measuring report including evaluation of the measured results and representation of the pump characteristic curve, amounts of leakage and wear condition of the individual hydraulic components

- Service report including recommendations on follow-up measures

- Replacement of components as required, e.g. valves and valve filters

- DORST TECHNOLOGIES will provide the necessary equipment, making it available for the duration of the check

- Our ample professional DORST diagnostic equipment consists of more than 400 components for a detailed analysis of all relevant hydraulic functions

- Our equipment includes all kinds of small parts that might be needed such as seals and O-rings

- A selection of hydraulic valves is available for prompt replacement in case of need

- Our mobile diagnostic equipment is available worldwide at all of DORST TECHNOLOGIES' business locations

Contact us.

Your contact