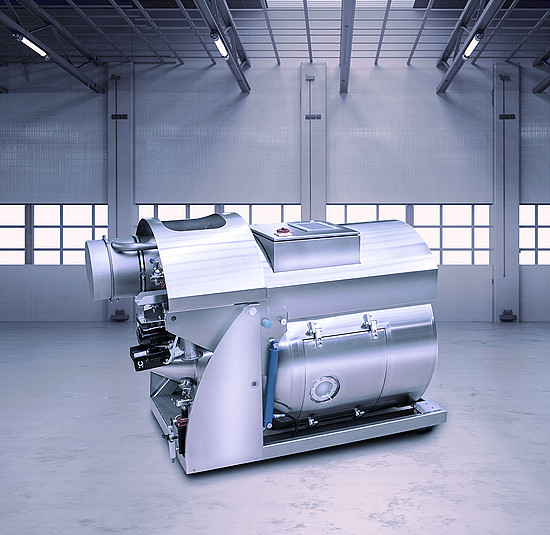

SMART Lab Atomizer Universal laboratory spray dryer for material development and pilot batch production

The SMART Lab Atomizer from DORST TECHNOLOGIES is the result of the intensive cooperation with our customers and is perfectly tailored to the special requirements of powder development in the laboratory environment.

Outstanding is the flexibility and mobility. As the world's first and only laboratory spray dryer, the entire spray dryer can be tilted 90° on its chassis. This means that the SMART Lab Atomizer can be used anywhere, even in confined spaces.

This flexibility allows easy access to all important points for operation, cleaning, set-up and maintenance - always safely and without stairs or ladders.

We have made a priority of ensuring that all functional units can be easily changed over by hand and without tools.

All parts that come into contact with the material are easy to clean or simple to replace.

We supply the SMART Lab Atomizer as a ready-to-use complete system with all accessories, nozzles, wash lance and suspension pump in a suitable stainless steel trolley. Simply connect to media and exhaust air and you are ready to go.

The SMART Lab Atomizer provides materials development with a unique system solution that can deliver comparable, scalable results for larger stationary production facilities starting at just one liter of water-based suspension.

The main area of application is in advanced technical ceramics, for silicate ceramic bodies and for hard metals.

However, the SMART laboratory dryer has also already proven its effectiveness in the powder preparation of graphite, minerals, salts, polymers and certain organic substances.

Advantages

- Plug & Spray

- All-in-one solution

- Easy cleaning

- Small footprint

- High flexibility

- Mobile device

Characteristics

Keyfacts

Technical information

Technologies

- Double wall insulated stainless steel reactor chamber

- Large access door

- Accessibility to all functional units without stairs or ladders

- Simple and easy handling

- Set-up without tools

- Interior lighting

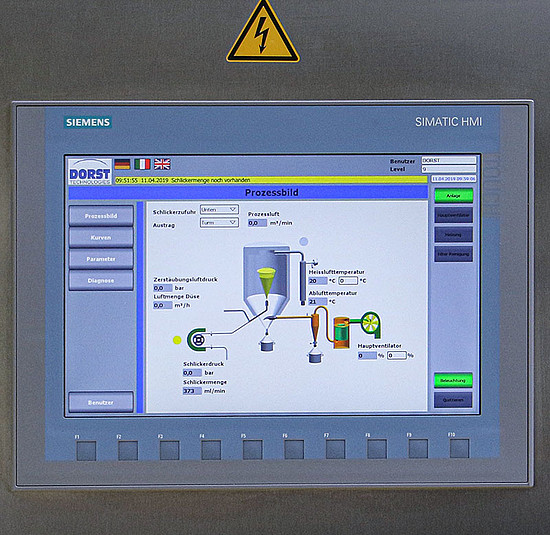

- Integrated control and visualization

- Interface for export of process data

- Plug & Spray

- All-in-one complete solution

- Mobile unit

- Tilting reactor chamber

- Wide range of applications

- Water evaporation capacity: max. 5 kg/h

- Input temperature: max. 320°C

- Cylindrical height: 1000 mm

- Inner diameter: 1000 mm

- Electrical heating power: 10 kW

- Dust extraction by cyclone and dry filtration

- Pump capacity: max. 0,37 l/min

- Weight: approx. 800 kg

- Water-based atomization drying

- Open system

- Nozzle atomization

- Countercurrent process

- Co-current process

- Granulate discharge via reactor cone and cyclone

- Granulate discharge only via cyclone

- Automated cleaning