WRM60/3 Pressure Casting System for Sanitaryware

Our pressure casting plant WRM60/3 with increased mold installation space is used for the efficient forming of water rims with integrated water tank for so-called one-piece toilets made of ceramic slip (e.g. vitreous china/VC and fine fire clay/FFC) by hollow or solid casting.

Thus, the WRM60/3 is a supplement to the pressure casting plant of the WCM60 series with the two machines together forming a functional system with joint control system.

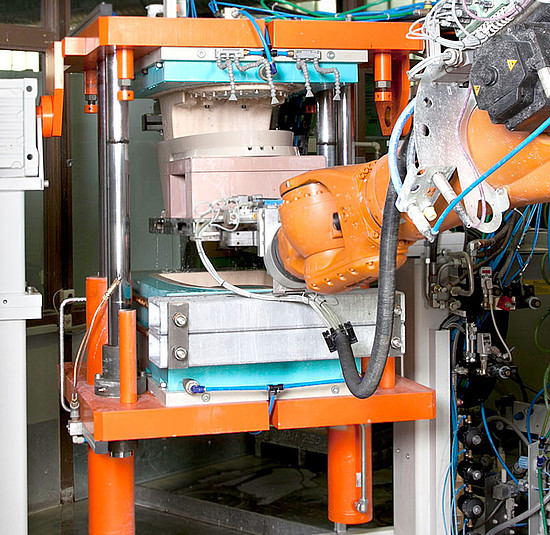

The machine is designed for molds made of porous synthetic material and consisting of two parts. In addition to that, an assistance robot can insert a third mold part in the area of the water tank. The articles will be cast in so-called upside-down position.

The mold parts will be brought together in horizontal position before being locked hydraulically. After that, the closed mold set can be rotated as desired up to a vertical position.

During casting, the closing pressure will be adjusted to the increasing slip pressure inside the mold.

The articles will be removed in a controlled manner and with little deformation by means of a robot.

During the casting process, the closing pressure follows the slip pressure inside the molds.

The articles are removed in a controlled and low-deformation procedure by a robot.

Advantages

- Suitable for hollow and solid casting

- Modular expansion possibilities

- Closing force adjustment

- Flexible and highly productive

- Energy-efficient and silent

Characteristics

Keyfacts

Technical information

Technologies

Removal

- Removal by robot

- Combination of up to three plants to one production cell with centralized robot

Modularity

- Combination with pressure casting plants for toilets of our WCM60 series

- Fixing of the rim by robot

- Application stations for sticking slip and suction stations for residual slip

Fettling and conveyor systems

- Article-specific setters and turning trays

- Storage racks

- Conveyor lines

- Fettling tables

- Auxiliary transfer devices for transport between fettling tables and conveyor lines

Producivity

- Highly efficient pressure casting plant for serial production

- Movable mold set

- High article quality due to removal in upside-down position with little deformation

- Ample mold mounting area for efficient removal and quick mold change

Energy efficiency

- Adjustment of closing pressure according to the slip pressure

- Minimum energy consumption at the casting stage

- No cooling of the hydraulic unit necessary

Usability

- Clearly structured process control with electronic variable programming system

- Number of Pressure casting molds: 1

- Closing force: max. 600 kN

- Casting pressure: max. 15 bar

- Mold block: max. 1000 x 700 x 460 mm

- Output: approx. 3 – 5 cycles per hour

- Sanitary pressure casting

- Solid casting

- Hollow casting

- Porous resin molds

Closing force adjustment